Calectro is proud to introduce the Uniguard 8.

Probably the smallest duct smoke detector in the world!

Calectro introduces the latest evolution of our market leading single tube duct smoke detector, the Uniguard. With a simpler installation, smaller and lighter housing and even better detection capabilities, the Calectro Uniguard 8 takes a leap from its predecessors and paves the way for a new generation of single tube duct smoke detectors.

Now in stock, ready for delivery!

Innovative new sampling tube!

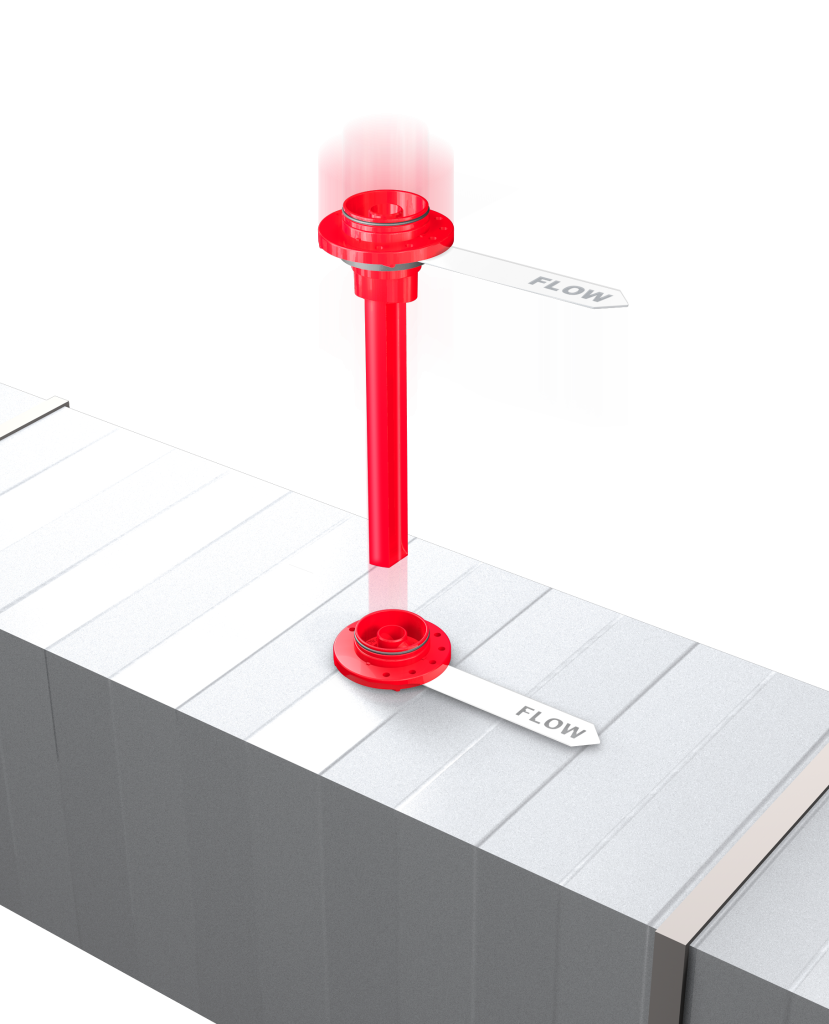

Meet PST195! Calectro’s new sampling tube for use in ventilation ducts together with Uniguard 8. PST195 can be used for installation regardless of duct dimensions without cutting or machining.

One tube for all ventilation ducts

The PST195 sampling tube provides effective collection of flue gases and is tested and certified according to both European standards (VdS) and American standards (UL). A small and flexible tube for both small and large ventilation ducts.

Faster installation

The new air sampling tube should not be cut and fits all duct dimensions, making the installation of Uniguard 8 quick and easy. For duct dimensions of Ø 200 mm or smaller, a mounting bracket is required.

Reduces your costs

PST195 reduces both logistics costs and the need for warehouse capacity. The tube is very light, weighing only 21 grams, which is a great advantage during both transport and installation.

Included in the package

The PST195 venturi tube is so small and light that it fits in the Uniguard 8’s packaging and from March 1, 2025, the tube will be delivered included in the packaging on all our UG8 models.

Short history of the Uniguard

Calectro started its development of duct smoke detectors back in 1978 by offering a dual tube system. This was our first duct smoke detector and became a very important product for our company. We have always tried to be innovative, attentive to our customers and lead the development in our market segment. In 1994 we developed our first Uniguard single tube system, designed for installation in ventilation ducts. This was a unique innovation, and the first smoke detector in the world to use a only one venturi tube. We are very proud of how revolutionary our product was then, and still is today. But time stands still for no one, so we at Calectro continue to lead the way and create innovative solutions for both our users and installers.

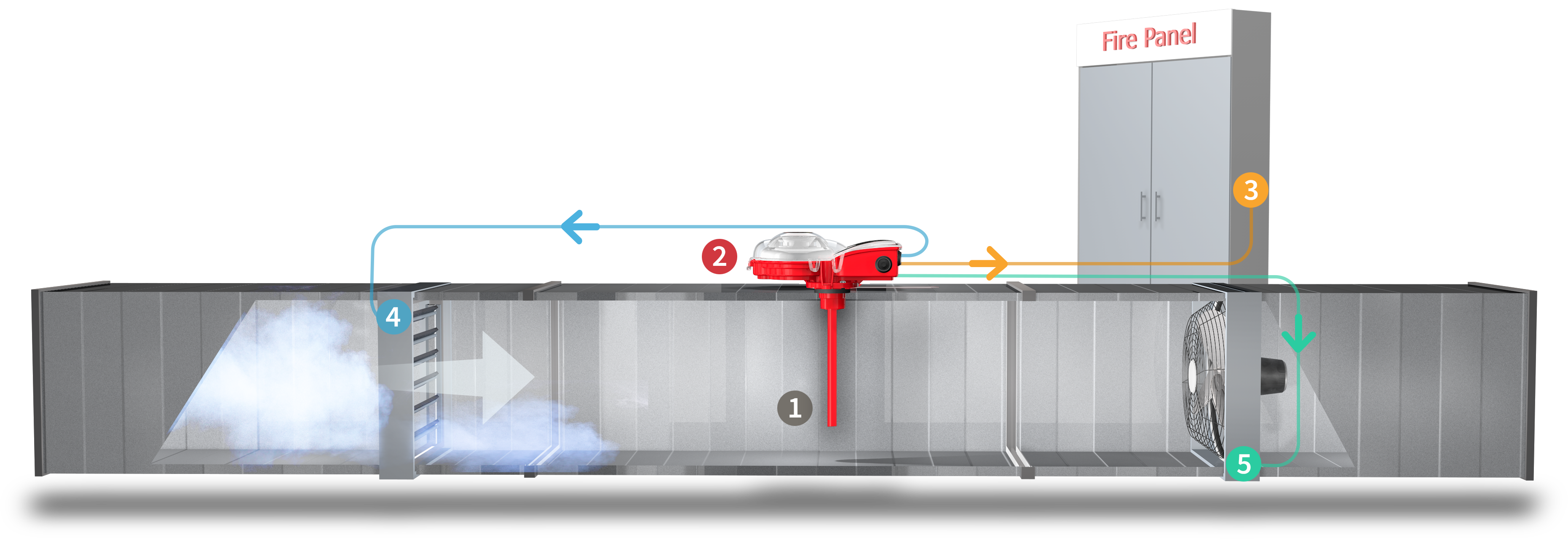

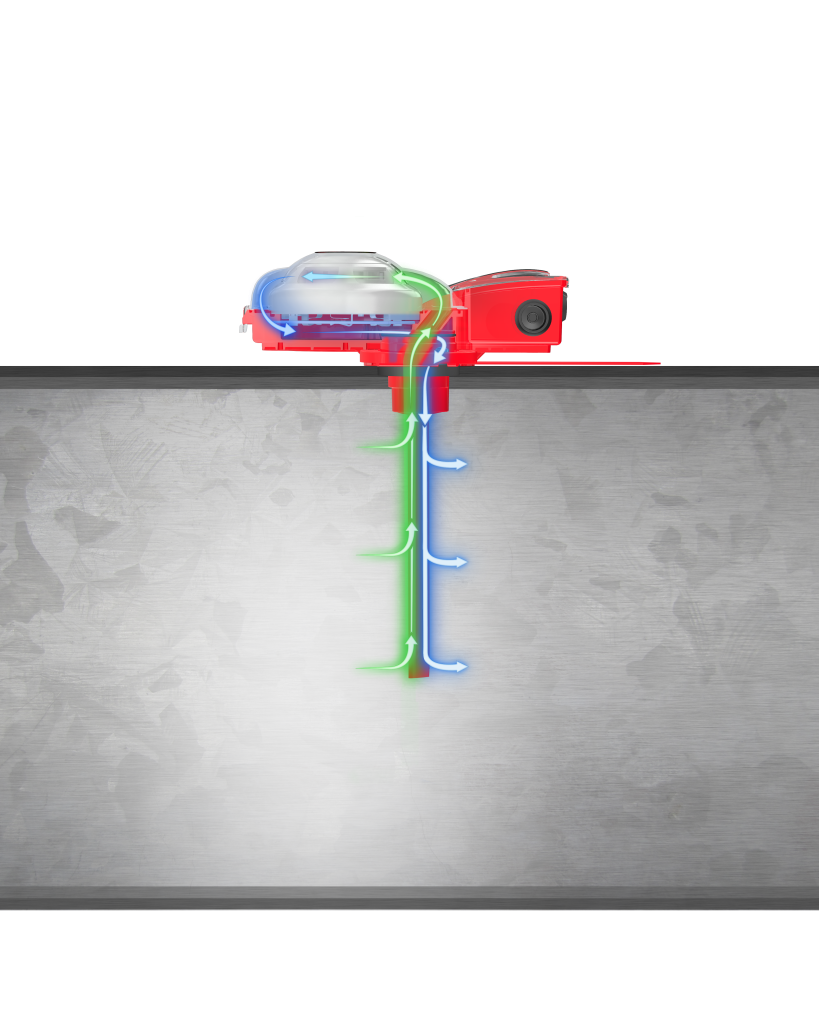

How does single-tube smoke detection work in ducts?

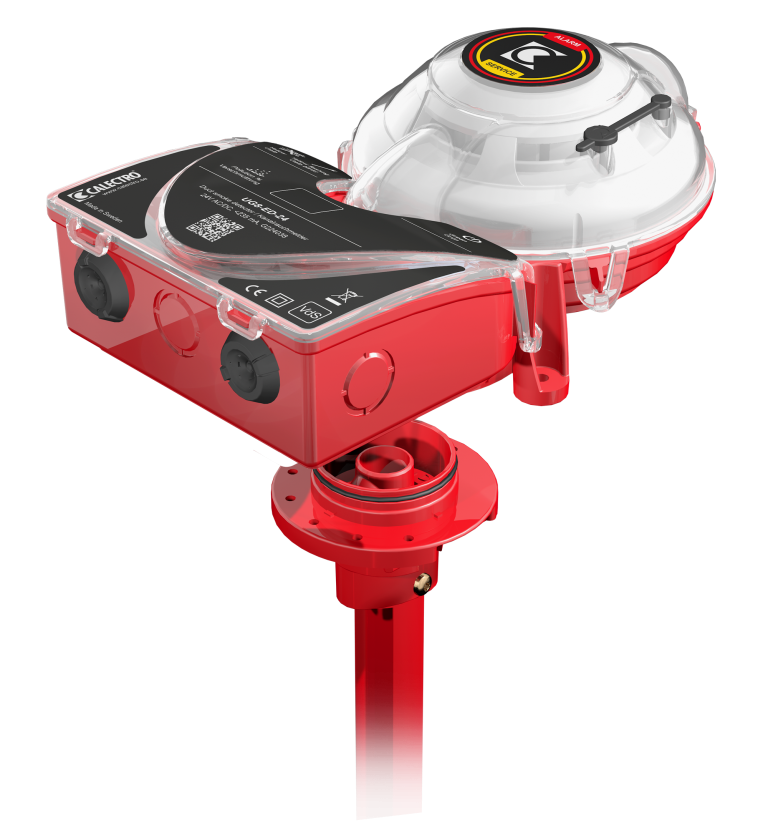

The system is based on an air probe (a so-called venturi tube) 1, a smoke detector housing with integrated control unit 2 (Uniguard smoke detector is also available with an external control unit) . The venturi tube conducts the air from the duct to the detector housing, which is fitted to the outside of the duct, where a smoke detector detects potential fire particles in the air. In the event of an alarm, the smoke detector sends a signal to the control unit, which by means of relays then closes dampers 4, stops/starts fans 5 and forwards the alarm, e.g. to the substation or a fire panel 3. The aerodynamic design of the housing and the sampling tube are crucially important for the ability to detect small levels of smoke particles in the air at an early stage.

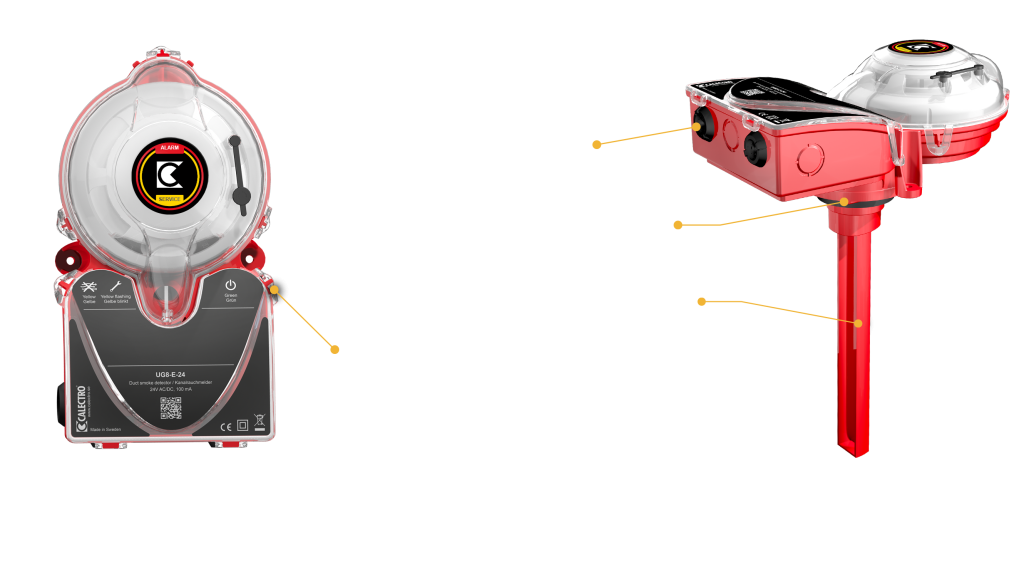

Uniguard 8's anatomy

Why Uniguard 8?

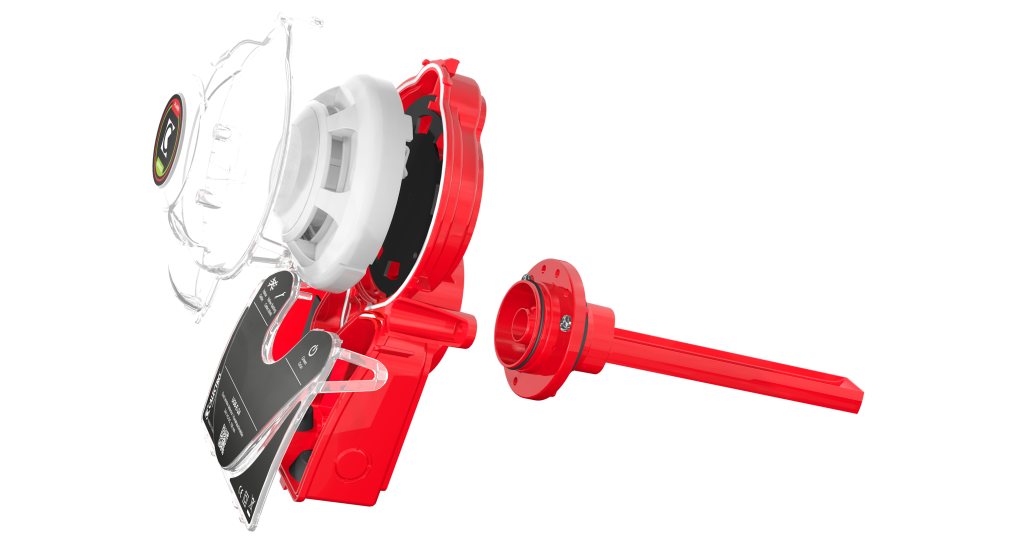

The Uniguard 8 is the result of over 50 yeas of dedicated development in the field of duct smoke detection. As the main purpose of smoke detection is to detect smoke in the ventilation ducts as early as possible so that counter measures can be taken, a high sensitivity for even the smallest amounts of smoke in the duct is paramount. But the system also needs notice the difference between a false alarm activated from smoke from for example a frying pan and that of a real alarm. The Uniguard 8 has, apart from world leading smoke detection, several functions to help and simplify the life of the user during the products life cycle, from installation to service. The toolless opening of the housings lids, electrical installation with spring loaded terminals for faster installations and a clear indication of the status of the system through strong LED lights are just a few of the improvements that the Uniguard 8 delivers. Another new feature for the Uniguard 8 is the patent pending rotation part that gives the possibility of a 360 degree rotation of the duct smoke detector, to make installations in tight places even easier.

Simple and fast installation

The new, patent pending, Uniguard 8 is designed to reduce the installation time to a minimum. With only one venturi tube that contains both inlet and outlet of the airflow, you only need to drill one hole in the duct. Easy access, snap on lids, spring loaded terminals, premounted cable glands and the new rotation device all simplify the installation process.

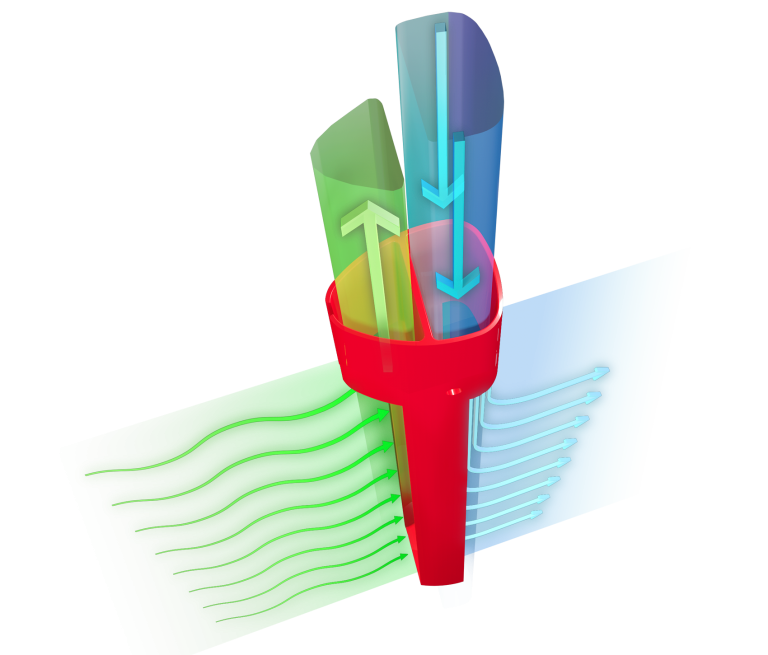

Advanced venturi tube technology

Uniguard’s patented venturi tube is fitted with aerodynamic flanges that are the most effective way of drawing air from the depths of the entire ventilation duct and delivering it to the smoke detector. This facilitates the discovery of flue gases even in small doses and at low air speeds. The effect of the venturi tube has been measured and doumented by external laboratories.

Flow-optimised housing

The Uniguard 8’s patent pending housing has been specially designed using simulation software to achieve a maximum concentration of flue gases around the smoke detector. Together with the patented venturi tube, the UG8 housing creates an unsurpassed detection performance, even at a very low duct air speed. It is also equipped with an air flow indicator for easy inspection.

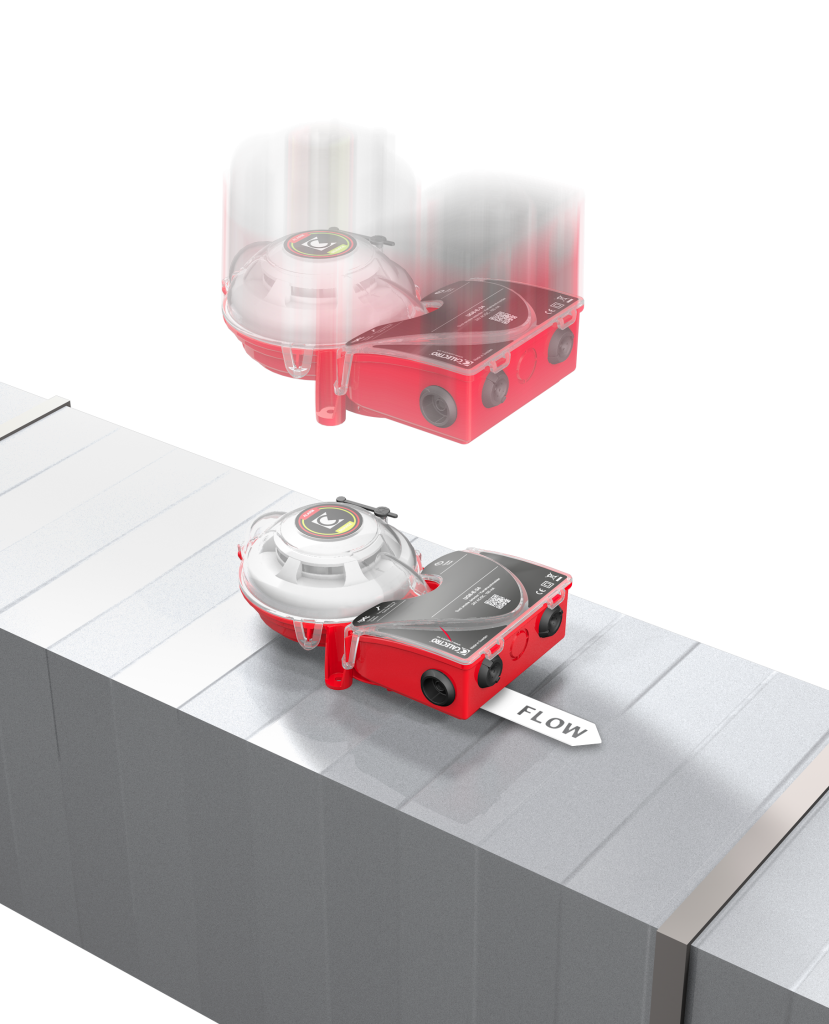

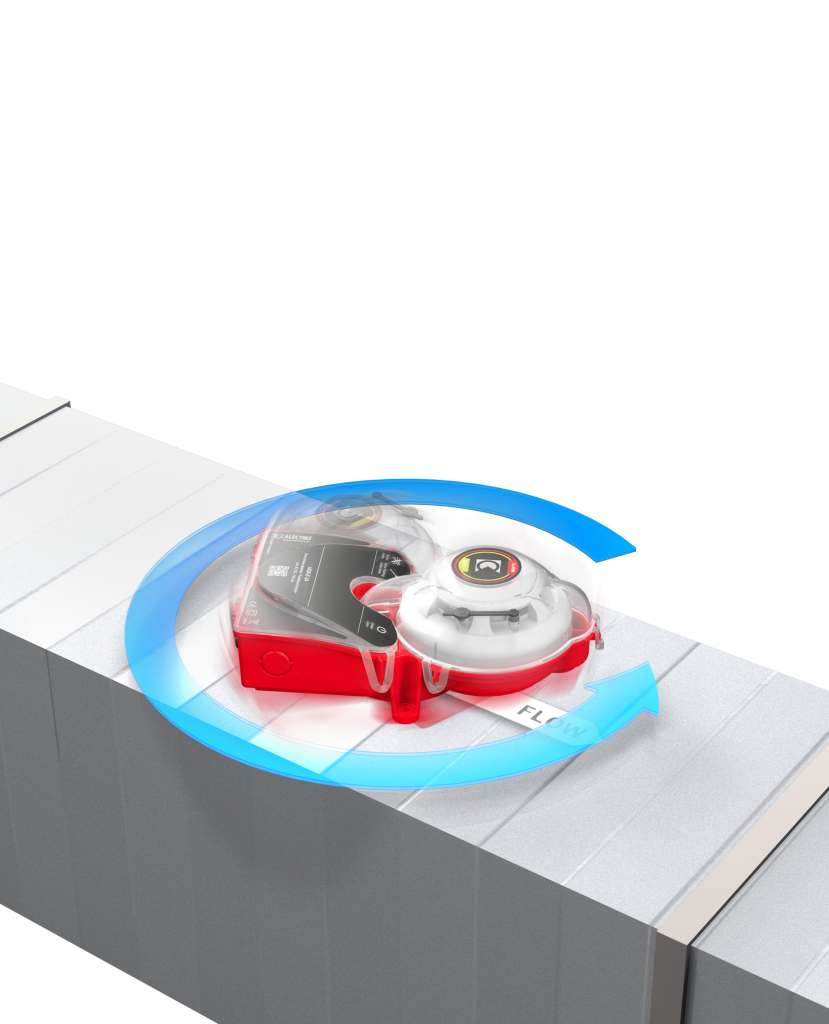

360 degrees mounting possibilities

One of the unique advantages of Uniguard 8 is its world-unique rotating part. This simplifies installation considerably as the venturi tube and detector can be installed separately. To make it easier to place in tight spaces, the detector can be rotated up to 360 degrees while the venturi tube and rotating part are kept fixed in the correct airflow direction.

This is how the rotation part works

First you drill a hole into the duct, then mount the rotation part together with the venturi tube with the screws.

Place the duct smoke detector on the rotation part.

The duct smoke detector can now be rotated around the rotation part for the optimal placement before being screwed in place.

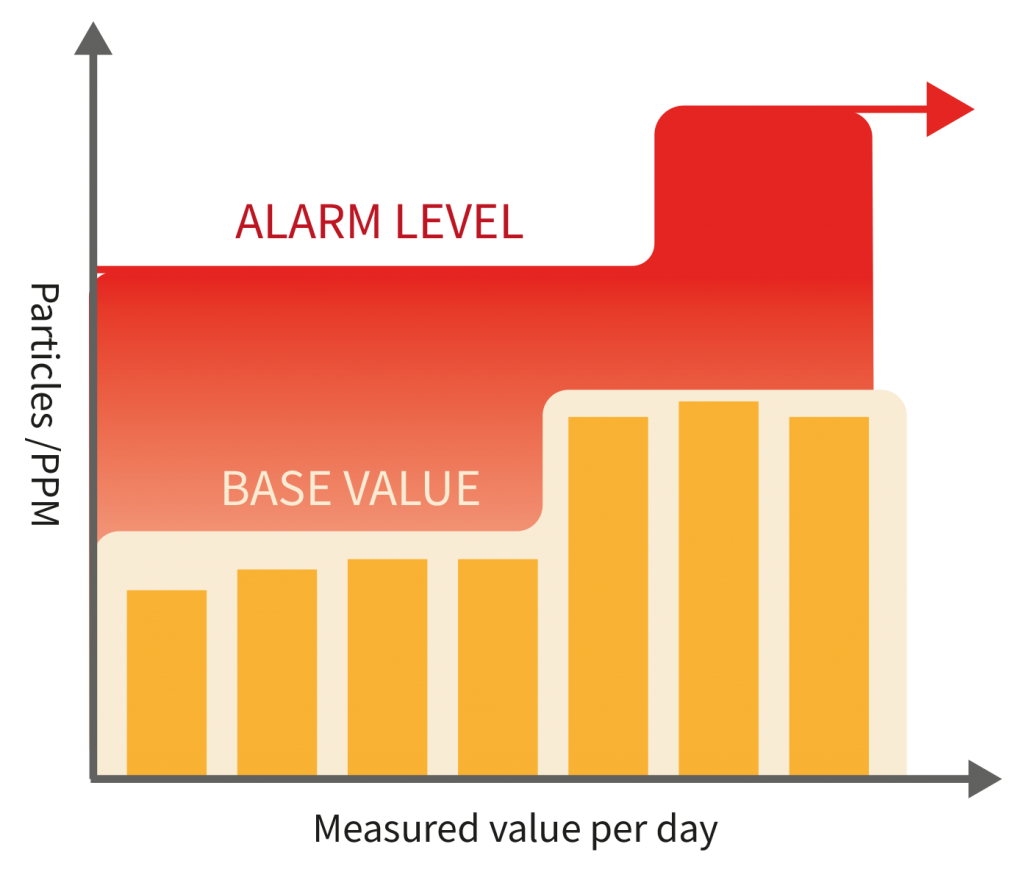

Automatic sensitivity adjustment

Uniguard’s smoke detectors have an inbuilt, automatic sensitivity adjustment that measures the base value in the air flow every day and compensates for any possible variations in the system over time. This minimises the risk of undesired alarms and unnecessary maintenance.

High protection class with IP65

Uniguard 8 is dust, water and weather resistant and can be installed in very tough environments.

Carbon footprint reduced by 50%

Compared to our previous models the weight and amount of plastic used has been halved. The reduction in size means that we can get more than twice as many on a pallet. This also results in reduced freight costs, warehouse spaces etc.

Designed and produced in Sweden

The Uniguard 8, like Calectro’s other products, are designed and produced in Sweden. This is what we at Calectro has done for over 50 years and contributes greatly to the high quality of the products, shorter transports and fast production.

Relaterade Produkter

Contact our sales staff

Business Dev. Manager Global Sales

Niclas Pettersson

Languages: SV, EN

+46 701-76 76 70niclas.pettersson@calectro.se

Export assistant - orders

Anja Oginsky

Languages: SV, EN, DE, IT

+46 31-69 53 13anja.oginsky@calectro.se