UL certified Duct smoke detectors

UG8-U-120

Optical duct smoke detector with service alarm and built-in control unit, 120V. Free-rotation in any direction.

- Need help? Contact us between 8 am – 4 pm every weekday (CET)

- 5-year product warranty

We arrange shipment to almost every country

We arrange shipment to almost every country

- Product information

- Documents

UG8-E-24

Description

The UG8 Uniguard has been developed to measure smoke in ventilation ducts and consists of a smoke detector and duct enclosure system, specially-designed for optimal airflow through the smoke detector.

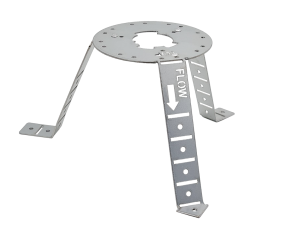

The Uniguard 8 has been developed to detect smoke in ventilation ducts. The UG8 contains a smoke detector that detects if the air in the ventilation duct contains smoke or fire particles. The sampling tube uses the venturi principle which, when mounted in the duct, creates an airflow that goes through the Uniguard as air moves through the ventilation duct. The Uniguard and the design of the sampling tube ensures detection even at very low air velocities, down to 100 ft/min (0.5 m/s).

The sampling tube and its rotation part is mounted separately on the duct. This facilitates installations in very tight places compared to other models on the market and previous Unigard duct smoke detectors, with integrated mounting of sampling tube.

The UG8 is only 76 mm high and can be turned in any direction (360º) on the rotation part, which makes the installation and connection of cables very convenient.

To make installations and services easy, the UG8 is equipped with snap-on lids over both the detector chamber and the connection terminals as well as push in terminals.

UG8 has built in relays for direct connection of safety functions such as fire dampers. There are also relays that are activated due to contamination and system failure. Reset of a smoke alarm is done via the reset button or a short circuit between RST and RST GND on the PCB.

Additional features of the UG8 which are beyond the UL requirements are a Low Airflow Alarm and an Automatic Sensitivity Adjustment. To activate the built in Low Airflow alarm, remove the jumper. The Low Airflow alarm relay will activate below approx. 250 ft/min (1.3 m/s) air velocity in the ventilation duct. The Automatic Sensitivity Adjustment is achived by a built in intelligent controlling circuit in the UG8. This enables a longer lifespan of the detector and fewer false alarms due to contamination.

Installation

The UG8 has a unique rotation function that allows mounting the UG8 in tight spaces. First mount the sampling tube and the rotation part, turned in the correct airflow direction of the ventilation duct. Then you mount the UG8 on the rotation part and turn it to the wanted position. Lock in place with two screws.

To achieve the optimal airflow through the UG8, place the UG8 as you would place an air flow meter. See the installation guide that comes with the product for more details.

Power Sampling tube (PST195)

The PST195, which is included with the product, is a “one size fits all” tube which fits all ducts with a diameter over 200 mm/8 inches and where there is air flow across the whole duct. Always make sure you have installed the duct smoke detector in the correct place by performing a test with artificial smoke in the duct. In some places you might have to use an aluminium sampling tube, such as the ST5, that penetrates the whole width of the duct or change the placement of the UG8 duct smoke detector. Please see instruction manual for more information.

Maintenance

When the detector is contaminated and the automatic sensitivity adjustment has reached its maximum level, further contamination will make the detector more sensitive. To avoid false alarms, due to contamination, the detector goes into service- / contamination alarm when it reaches two thirds alarm signal value. Depending on the type of contamination, cleaning it once per year with a vacuum cleaner can prolong the life span of the detector.

A functionality test is recommended after completed service and installation. Test that the detector goes into alarm and is installed in the correct way. The test can be made with smoke detector test spray by giving a short burst through the test port in the smoke detector lid. Do not forget to replace the test port plug afterwards.

Properties

- Sampling Tube for all ducts over 8” included

- Single tube system

- IP65 dust and water proof

- Easy installation

- 360° mounting possibilities

- Patent pending rotation & mounting device

- Automatic sensitivity adjustment

- Contamination alarm

- Built in alarm-relays

- 4 relay contacts

- Easy service and maintenance

- Test port for aerosol spray on cover