Prevent smoke from spreading in facilities by using smoke detectors in ventilation ducts

2021-02-17

Smoke from a typical fire in a facility often contains hundreds of different hazardous chemicals and fumes. As a result, the damages caused by the smoke can often exceed the damages caused by the actual fire. Smoke detectors in ventilation ducts are an excellent solution for detecting smoke at an early stage and preventing it from spreading.

Save lives and property with duct smoke detection

A smoke detector is an invaluable tool to limit the spread of smoke in a facility. By detecting smoke at an early stage there is a bigger chance to conduct a fast and controlled evacuation of a facility and, in turn, save both lives and property.

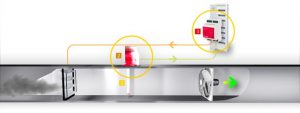

A ventilation system is an exposed area as it more or less connects the ventilation of all rooms and fire cells in a facility. Large airflows continuously pass through a ventilation system, which means that smoke and hazardous particles can quickly spread from one room to the rest of the facility by passing through the ventilation channels. To avoid this, smoke detectors in ventilation ducts are key. When smoke is detected, the smoke detection system sends an alarm to the control unit and DDC (Direct Digital Controller). These can then quickly implement countermeasures such as closing dampers and initiating forced ventilation in order to limit the spread of smoke.

A venturi tube, a smoke detector housing, and a control unit

Smoke detectors in ventilation ducts are basically needed in all buildings that have ventilation systems such as offices, hospitals, department stores as well as schools. In new buildings, the smoke detectors and ventilation systems are often installed at the same time. In existing buildings, they can be installed during, for example, reconstructions and renovations. A smoke detector system consists of an air probe (a so-called venturi tube) 1 and a smoke detector housing 2 with an integrated or external control unit 3 . It is a closed system as air from the ventilation duct enters the venturi tube, passes through the smoke detector and returns through the venturi tube back to the ventilation duct.

Optical smoke detectors use photosensors to analyze the air

The first smoke detectors on the market contained radioactive substances which of course were harmful to the environment. Since then, the design of the smoke detector has developed into, for example, optical detectors measuring the air with light instead of radioactivity. A photosensor senses the light inside the detector and reacts if smoke enters the detector as the smoke creates a reflection of the light. This increases the amount of light hitting the photosensor which starts the alarm on the smoke detector.

Since the smoke detector continuously analyzes large amounts of air, it will eventually get dirty and needs to be replaced. In order to prolong the lifespan of the smoke detector and making it more sustainable, all Calectro’s duct smoke detectors have a built-in automatic sensitivity adjustment. It is also advised to clean the equipment every other year. Aside from being sustainable, smoke detectors for ventilation ducts must be easy to install and require minimal service.

Calectro’s Uniguard detects smoke in airflow speeds from 0.2 m/s to 20 m/s

Calectro has many years’ experience working with duct smoke detection. Our smoke detection systems, called Uniguard, are adapted to most countries’ specific rules. One of our most popular smoke detectors for ventilation ducts is our UG-3-O, which has an intelligent monitoring circuit that continuously checks and adjusts the sensitivity for optimum functionality during the entire life span of the detector. The system fulfills all the requirements for excellent smoke detection with airflow speeds from 0.2 m/s to 20 m/s. Calectro’s UG-3-O is an excellent example of a product that helps you detect smoke in your ventilation ducts quickly, allowing you to implement countermeasures such as closing dampers in order to limit the spread of smoke.

I hope you enjoyed reading my article about smoke detectors in ventilation ducts. Feel free to visit our website for more information and to learn more about Calectro’s products. Also, we would love for you to say hi on our social media, Linkedin, Facebook, Instagram and YouTube!

Explore our various Uniguard duct smoke detectorsRelated articles

-

Fundamentals

2021-03-03

How important is good ventilation? Very.

Read more