Air pressure measurement

Accurate measurement is the be-all and end-all if a ventilation system is to function optimally. The CPS is Calectro’s differential pressure sensor that measures pressure accurately and with temperature compensation, and then reports to a control centre. Thanks to our excellent understanding of the needs that an installer can face, the CPS has been developed from the outset with functions that facilitate installation and calibration.

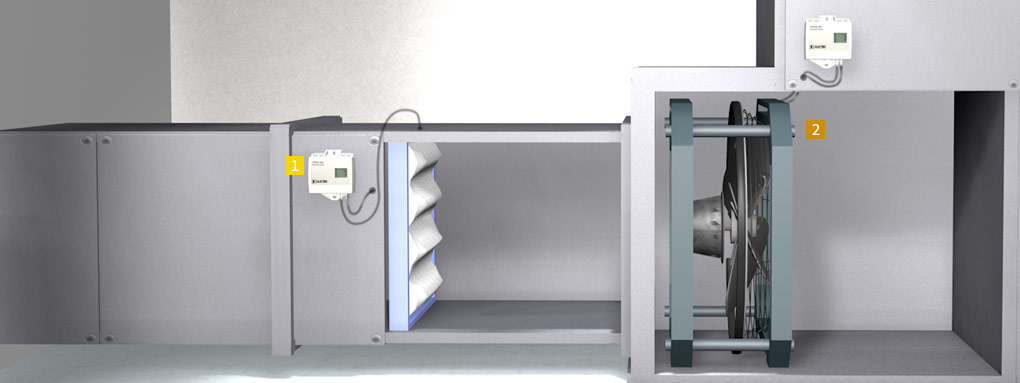

How does the application work?

The CPS differential pressure sensor can be used, for example, to measure as shown in the image below: The CPS measures pressure before and after filters 1 , and also through the fan 2 . The pressure sensors report their values to a control centre, which in turn adjusts the fan’s speed to achieve optimal effect with the lowest possible energy consumption

Why choose Calectro’s differential pressure sensor?

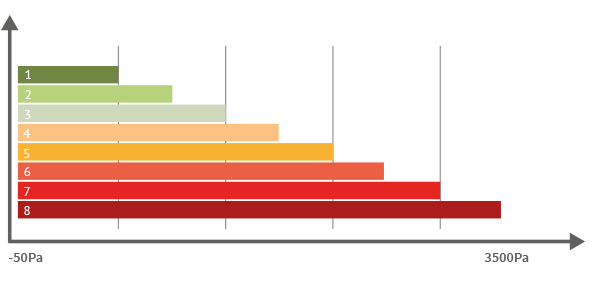

One device, several pressure ranges

The CPS can measure differential pressure over a very broad pressure range. The measurement values are temperature-compensated for high accuracy and linearity. There are eight different measurement ranges from which to choose.

Clear backlit display

There is a version of the CPS with a backlit display (CPS-D-A) for easier configuration and reading. The CPS-D-A can also be programmed to show litres per second or m3 per hour. The display can also be programmed to show current pressure and current output signal as a percentage alternately.

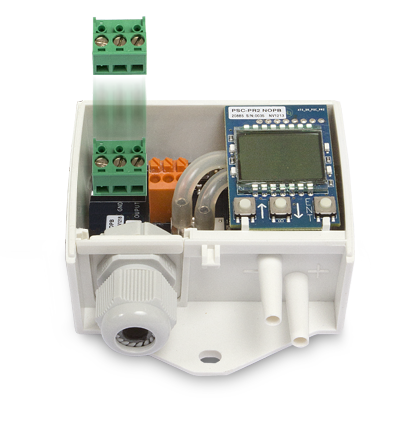

Detachable terminal block

The CPS has a detachable terminal block and cable port for easier installation in confined spaces. The lid on the enclosure also has a hinge with catches on the upper edge to keep the lid open when raised.

MODBUS

Modbus is a communication interface that allows for central monitoring and control of all devices connected in a network. The pressure sensor with display (CPS-D-MB) has Modbus communication via RS485 as standard.